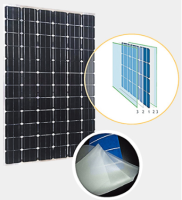

Anti PID (SV-15296P & SV-15297P)

Changzhou Sveck Photovoltaic New Materials Co, Ltd.| Type: | Ultra Fast Cure |

|---|---|

| Region: |

China

|

Note: Your Enquiry will be sent directly to Changzhou Sveck Photovoltaic New Materials Co, Ltd..

Alternative Product

P507 for P-per...

HIUV New Materials

From

€1.49 / m2

- Thickness: 0.5-0.7 mm

- Type: Fast Cure

- Width: ≤1100 mm

- Roll Length: 100-200 m

- VA Content: 12-18 %

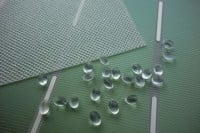

Product Characteristics

| Product Characteristics | |

|---|---|

| Type | Ultra Fast Cure |

| Thickness | 0.45-0.9 mm |

| Roll Length | 100 m |

| Density | 0.96 g/cm3 |

| Gel Content | ≥75 % |

| Stability Characteristics | |

| Tensile Strength | 16 Mpa |

| Elongation | 550 % |

| Peel Strength (Encapsulants-Glass) | ≥60 N/cm |

| Peel Strength (Encapsulants-Backsheet) | ≥40 N/cm |

| Thermal Shrinkage (Length / MD) | ≤3 % |

| Thermal Shrinkage (Width / TD) | ≤2 % |

| Volume Resistivity | >1x10 ^14 Ω·cm |

| UV Aging (Yellowish Index) | ≤2 △YI |

| Optical & Thermal Characteristics | |

| Light Transmittance | ≥80 % |

Changzhou Sveck Photovoltaic New Materials Co, Ltd.

Related Products

-

White EVA fil...

Sveck Photovolt... Ultra Fast Cure -

€1.16 / Wp

€1.16 / WpEVA Film - Ul...

Dr. HWC Ultra Fast Cure -

White II EVA ...

Sveck Photovolt... Ultra Fast Cure -

€1.27 / Wp

€1.27 / WpEVA film tran...

Feiyu EVA Ultra Fast Cure -

PO film (SE-5...

Sveck Photovolt... Fast Cure -

Sinopont EVA ...

Sinopont Techno... Standard Cure -

PO II FLIM (C...

Sveck Photovolt... Ultra Fast Cure -

POE

Sinopont Techno... Standard Cure