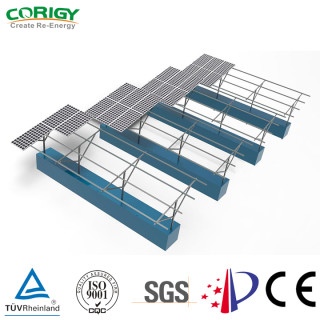

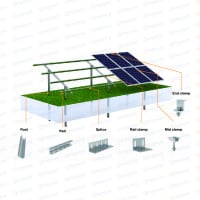

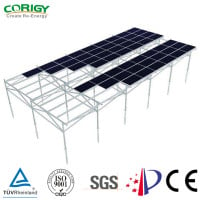

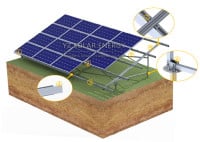

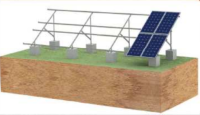

CP-GM5 Single-Pole Ground Mount System

Xiamen Corigy New Energy Technology Co., Ltd.| Region: |

China

|

|---|

Note: Your Enquiry will be sent directly to Xiamen Corigy New Energy Technology Co., Ltd..

Alternative Product

Ground Solar Mount (OE...

Soeasy Photovoltaic

From

€0.037

/ Wp

- Type: Ground

- Product Warranty: 10 Years

- Tilt Angle: --

- Wind Load: 252 km/h

- Snow Load: 1.5 kg/m2

Product Characteristics

| Model No. |

|

|

|---|---|---|

| Product Warranty | 10 Years | |

| System Overview | ||

| Type | Ground | |

| Mounting System Arrangement | Rows, Columns | |

| Panel Framing | Framed, Unframed | |

| Panel Orientation | Portrait, Landscape | |

| Roof Types | Concrete | |

| Tilt Angle |

|

|

| Maximum Terrain Slope |

|

|

| Wind Load |

|

|

| Snow Load |

|

|

| General Data | ||

| Supporting Structure Materials | Aluminium, Stainless Steel | |

| Small Parts Materials | Aluminium, Stainless Steel |

Related Products

-

Tin Roof Sola...

Corigy Solar Pitched Roof -

€0.0272 / Wp

€0.0272 / WpMg-Al-Zn Grou...

Huge Energy Ground -

CP-KC Alumin...

Corigy Solar Ground -

€0.0171 / Wp

€0.0171 / WpHQ-GT4 Double...

HQ Mount Tech Ground -

CP-C Carport

Corigy Solar Carport -

€0.027 / Wp

€0.027 / WpPosMAC Solar ...

ExtenSolar Ground -

Tile Roof Sol...

Corigy Solar Pitched Roof -

€0.0278 / Wp

€0.0278 / WpGQ-F Series F...

Guoqiang Singsun Ground -

Agricultural ...

Corigy Solar Ground -

€0.0341 / Wp

€0.0341 / WpGS-Ground Mou...

Grace Solar Ground -

GM4 Ground So...

Corigy Solar Ground -

€0.037 / Wp

€0.037 / WpGround Solar ...

Soeasy Photovol... Ground -

GM3 Steel Sol...

Corigy Solar Ground -

€0.0282 / Wp

€0.0282 / WpGQ-A Fixed Ad...

Guoqiang Singsun Ground -

PV Mounting S...

Corigy Solar Ground -

€0.0261 / Wp

€0.0261 / WpGM-01 Ground ...

Young Zone Solar Ground -

CP-T Adjustab...

Corigy Solar Flat Roof -

€0.0293 / Wp

€0.0293 / WpGM-06 Galvani...

Young Zone Solar Ground -

CP-NRB Ballas...

Corigy Solar Flat Roof -

€0.0298 / Wp

€0.0298 / WpHot dip galva...

Huge Energy Ground -

Flat roof sol...

Corigy Solar Flat Roof -

€0.0274 / Wp

€0.0274 / WpGA2 Ground So...

9Sun Solar Ground -

CP-FT Metal R...

Corigy Solar Pitched Roof -

€0.0376 / Wp

€0.0376 / WpSolar Farm Mo...

9Sun Solar Ground -

Mini Rail Met...

Corigy Solar Pitched Roof -

€0.0996 / Wp

€0.0996 / WpKST-1P Single...

Kseng Solar Ground -

Floating moun...

Corigy Solar Floating -

€0.0254 / Wp

€0.0254 / WpGround Solar ...

Empery Solar Ground