UL-295-320M-60

Ningbo Ulica Solar Co., Ltd.| Type: | Monocrystalline |

|---|---|

| Power Range: | Wp |

| Region: |

China

|

Alternative Product

S Nano S430-44...

Shinson Technology- Cell Type: TOPCon

- Dimensions: 1762x1134x28 mm

- Weight: 20.5 kg

- Cell Size: --

- Glass Thickness: --

Product Characteristics

Useful Contacts

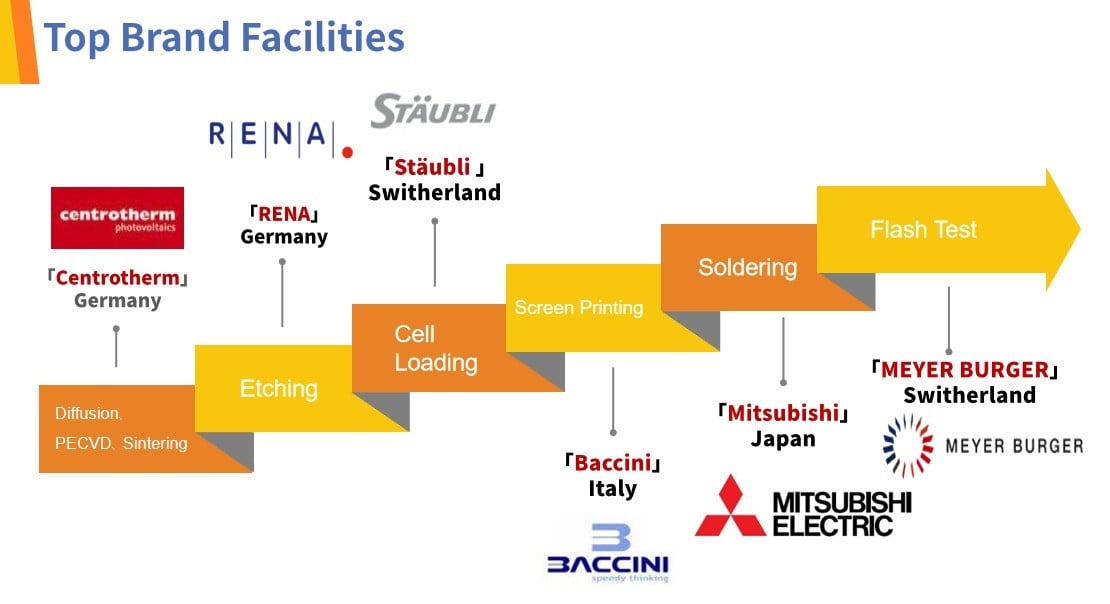

Technology & Equipment

We are cooperating with some of the world-famous equipment suppliers, such as Centrotherm, Baccini and Gorosabel, which are all the top-ranking global suppliers of PV equipment. We have brought in the most advanced and brand-new equipment from them.

The business partnership with these famous suppliers is the prerequisite for us to provide high-quality products.

As the leaders in PV equipment, our suppliers have many years of experience in this industry and enjoy a very high global reputation. Their websites are as follows:

Quality & Certificates

We attach much importance to the quality of our products. With the quality policy of client satisfaction, quality first, technological innovation and pursuit of better, we make quality assurance and improvements throughout the whole production process and have won wide praise among our clients. Generally, there are two items, namely quality prevention and quality inspection, for quality control. To assure quality, the quality control procedure is composed of Incoming Quality Control, In-process Quality Control, Quality control for Semi-products, Final Quality Control, Outgoing Quality Control, and Quality Audit.

We have obtained many important international certificates, such as CE, IEC61215 & 61730/TüV, UL, ISO9001, etc. Our quality concept is that good quality is the only way out of business survival and development. With continuous quality improvements and the participation of all the staff, we do our utmost to make our quality among the best in this industry. About Solar module certifications, please click to download.

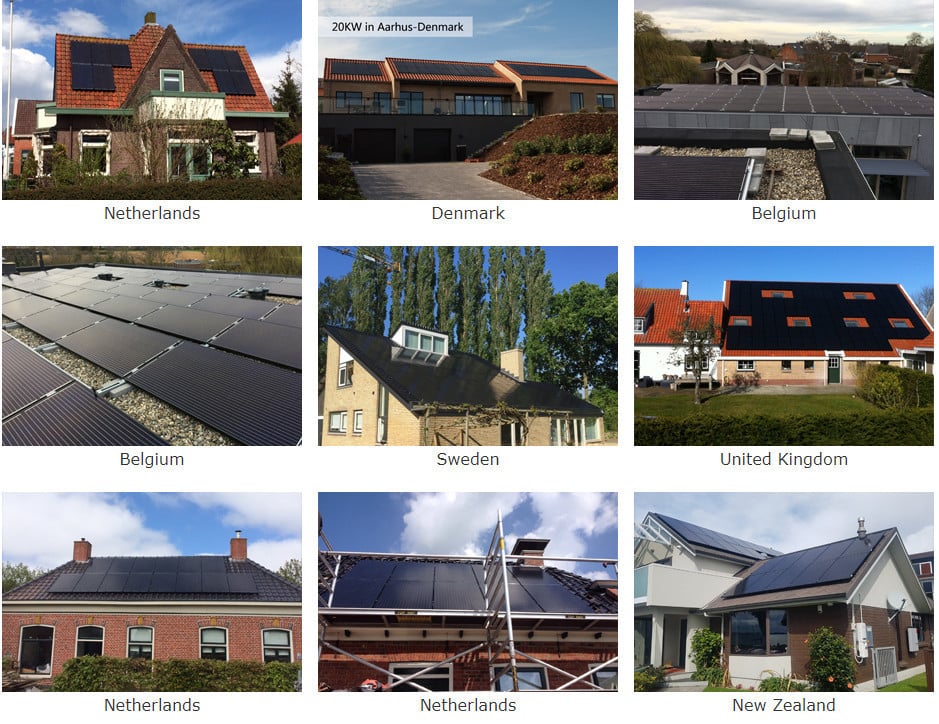

Ulica's modules have been applied in a wide range of applications including large-scale ground-based systems, roof systems, BIPV systems and others, both on-grid and off-grid.

10 More Series From Ningbo Ulica Solar Co., Ltd.

-

€0.122 / Wp

€0.122 / WpUL-440-455M-1...

440~455 Wp Bifacial, TOPCon -

€0.118 / Wp

€0.118 / WpUL-450~465M-1...

450~465 Wp TOPCon -

€0.117 / Wp

€0.117 / WpUL-610-620M-1...

610~620 Wp Bifacial, TOPCon -

€0.125 / Wp

€0.125 / WpUL-430~440M-D...

430~440 Wp Bifacial, TOPCon -

€0.123 / Wp

€0.123 / WpUL-430~440M-1...

430~440 Wp Bifacial, TOPCon -

€0.113 / Wp

€0.113 / WpUL-450~460M-1...

450~460 Wp Monocrystalline -

€0.112 / Wp

€0.112 / WpUL-545-555M-1...

545~555 Wp Monocrystalline -

€0.118 / Wp

€0.118 / WpUL-570~580M-1...

570~580 Wp Bifacial, TOPCon -

€0.108 / Wp

€0.108 / WpUL-655-670M-1...

655~670 Wp Monocrystalline -

€0.113 / Wp

€0.113 / WpUL-655-670M-1...

655~670 Wp Bifacial, PERC