Spire Solar LLC

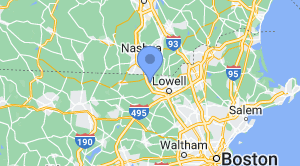

| 300 Potash Hill Road, Tyngsboro, MA 01879 |

| Click to show company phone |

| www.spiresolar.com |

United States  |

Staff Information

No. Staff

50

Useful Contacts

Robert Jan Van Vugt

Marketing Manager

Business Details

Equipment Types

Crystalline Panel Production Equipment:

Panel Solar Simulator

Parent Company

Eternal Sun Group

Last Update

26 Mar 2020

Company News

Financial News (9)

Purchasing Contracts (1)

Sales Contracts (2)